Review

Automated production processes, in-house testing and development laboratory – MZ Aspiratori guarantees high quality fans that provide high performance and low energy consumption.

Production technologies

Metalworking

All fan components are completely manufactured in the company, which has 2 automatic laser cutting workshops, mechanical and hydraulic presses with a capacity of up to 500 tons (which allows pressing all parts up to 1800 mm in size), press brakes, one press cell is fully automated and rollers for axial fans.

Welding

It is of strategic importance in the production process of fans, most of the welding work is carried out in 8 robotic areas, 3 for small parts of the fan, 2 for impellers and 3 for housings, the remaining operations are carried out by qualified personnel, based on a license issued by the Italian Institute of Welding (IIS) ) according to UNI EN287-1

Sandblasting and painting

Standard painting of fans: made on the basis of Qualicoat polyester powder with polymerization at 200 ° C, average thickness 70 microns; Pre-cleaning: phosphating and degreasing the metal or shot blasting (2.5 granules), or both methods used together. The average thermal resistance of the coating is 150 °C with peak values up to 180 °C. The impellers are coated with gray paint with an average thermal resistance of 150 °C.

Balancing

All impellers manufactured by MZ Aspiratori are balanced statically and dynamically in accordance with ISO 21940/11 standards, indicating a balancing degree of 6.3. The permissible residual eccentricity values are plotted for the entire impeller and must be equal on both planes in order to have correct dynamic tolerances. From the residual eccentricity value it is easy to return to the imbalance weight value.

Testing

All fans operate on alternating current up to 450 kW power and are verified by testing followed by vibration monitoring. This control is carried out in accordance with ISO14694 cat.BV-3 standards, and a vibration test report is issued at the customer's request.

Research and Development

Research and development of new products and production processes is today the driving force of the company, devoting many resources to product development in order to improve quality while reducing costs. Improvement of production processes, as well as standardization of parts, through the study of the technical department in collaboration with production managers. This constant exchange of ideas and information between departments allows the company to be extremely flexible, going directly to the root of the problem and solving it in a short time. Much attention is paid, of course, to increasing the hydrodynamic characteristics of fans.

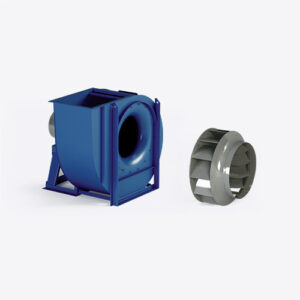

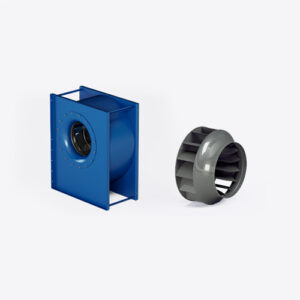

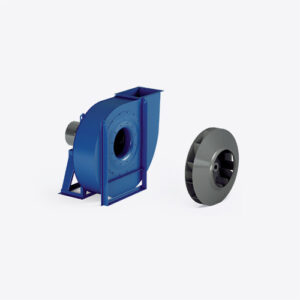

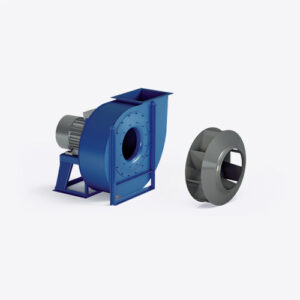

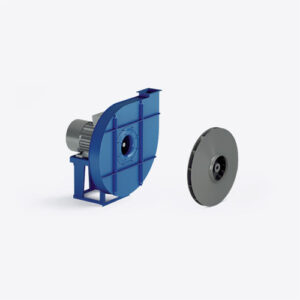

Low and medium pressure fans

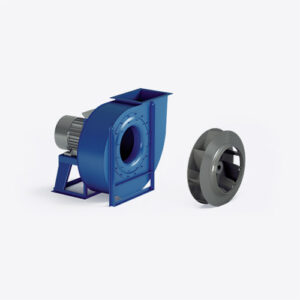

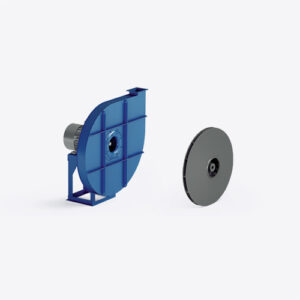

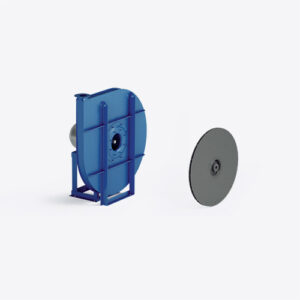

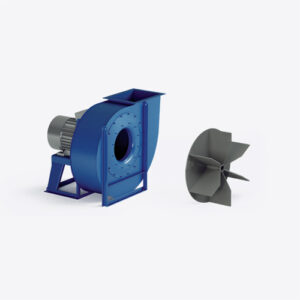

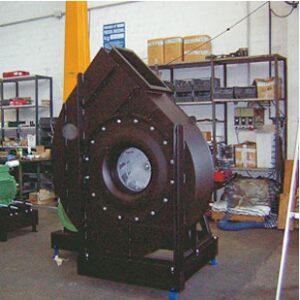

High pressure fans

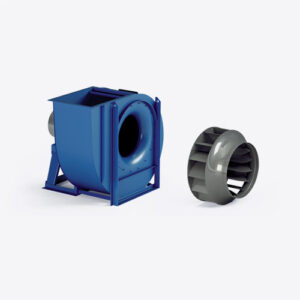

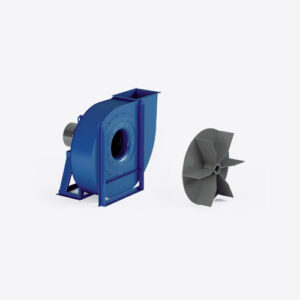

Transport fans

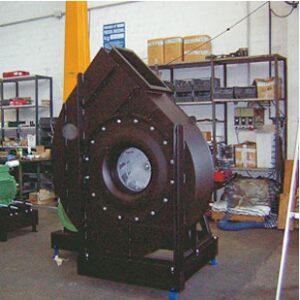

Our projects