BAUFLEX ENGINEERNIG offers advanced solutions for industrial gas cleaning systems, which are designed to meet the most complex requirements in various industries.

Combustion processes aimed at producing thermal energy, as well as electricity in thermoelectric and cogeneration plants, emit a significant amount of particulate matter invisible to the human eye. We are talking about PM (particulate matter), a complex of substances present in the air, which is especially dangerous because, being very thin, it penetrates the human body, reaching the lungs. Depending on the exposure a person is exposed to, a variety of health problems may occur, including cardiovascular and pulmonary disease. The only way to minimize the harmful effects of combustion during industrial processes is to equip plants with smoke filtration systems installed after the burner.Review

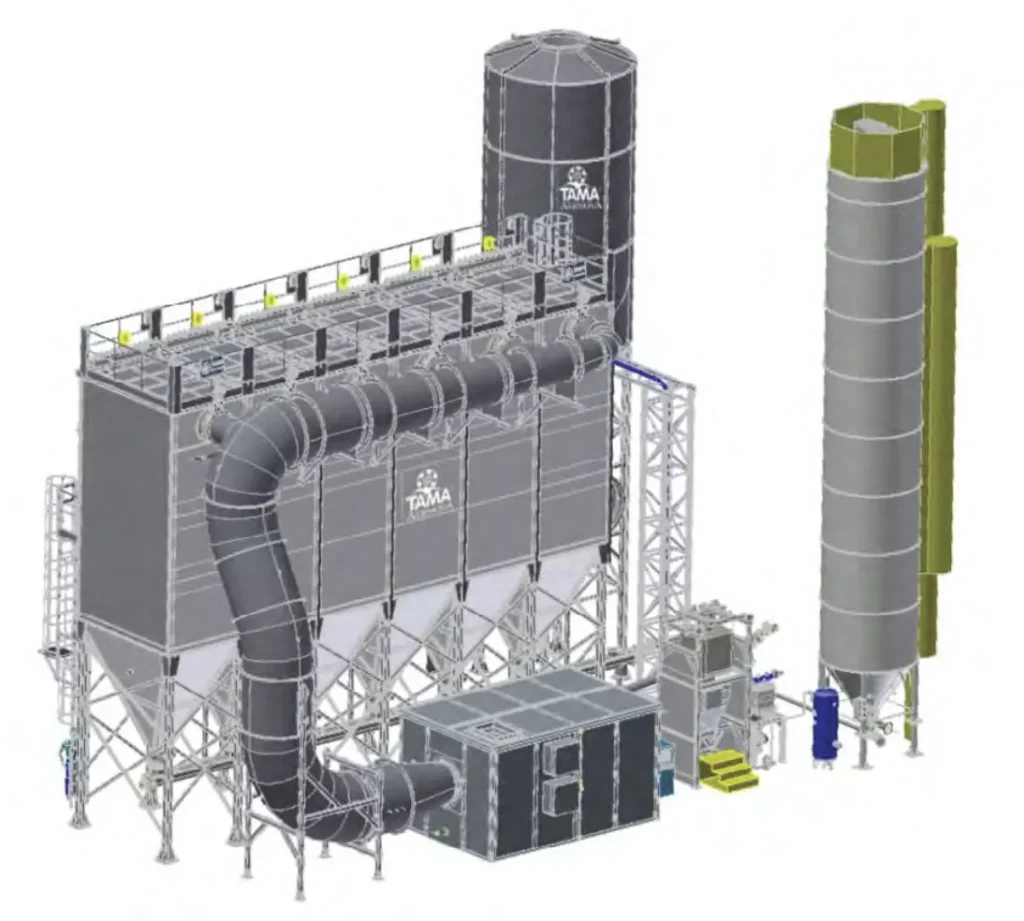

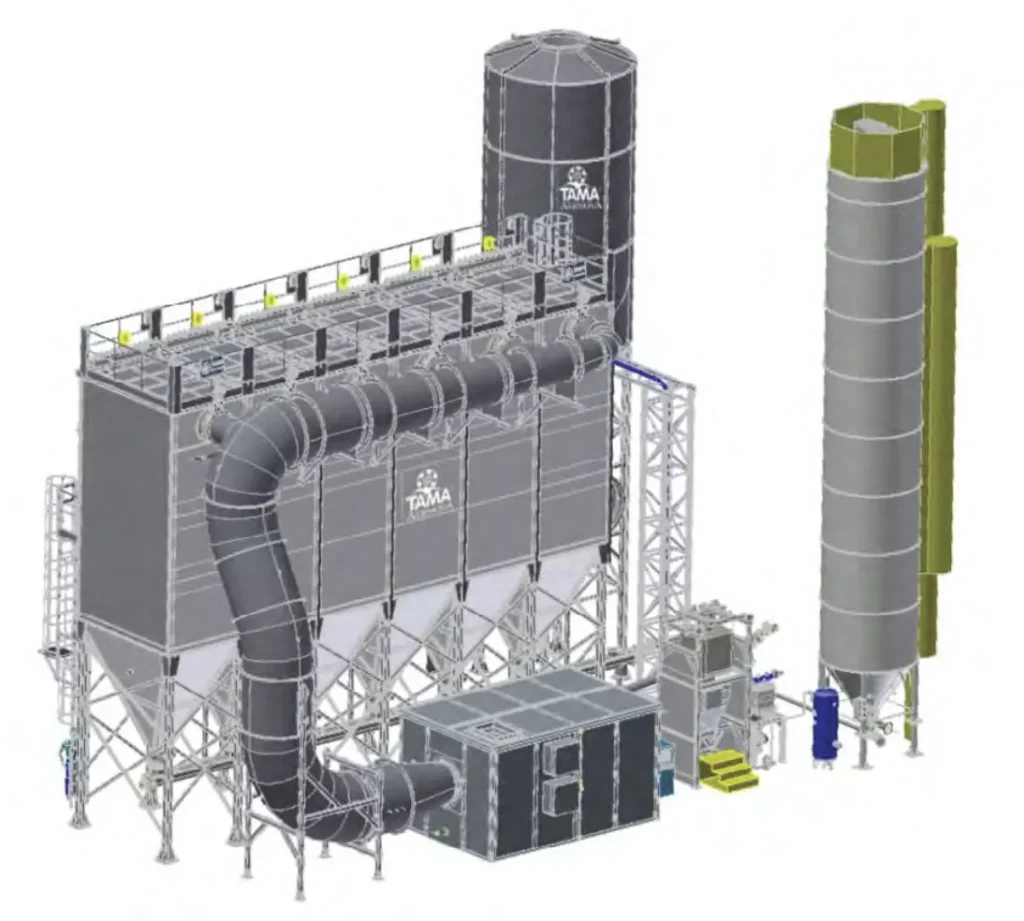

Bag filters for gas purification

This is a dry filtration system designed to clean air from substances in combustion processes. Its installation guarantees the air quality in industrial premises and the protection of people working in them.

Filter elements are cleaned by reading the pressure drop, which helps reduce compressed air consumption and increase the service life of the hoses.

High temperature painting and appropriate components allow it to be used at temperatures up to 250°C.

Advantages:

• Mineral wool insulation and cladding

aluminum sheets

• A fire extinguishing system is provided and

temperature probe

• Unloading and transportation of ash through

rotary valves and augers

• Suitable for indoor and outdoor installation

premises

• Transportable and quick installation

• Stairs and platforms for maintenance on

roof or in front of the filter

• Heating cable in the hopper for

temperature maintenance

• Level sensors

• Pneumatic vibrators in the hopper for

facilitating ash unloading

• Electrical probes

• Possibility to integrate ash unloading via pneumatic transport

• Pre-heating system

Cartridge filter

Its installation guarantees the purification of a wide range of pollutants. Filter elements are made of metal and eliminate any risk of fire inside the filter. The pulse jet cleaning system is controlled by a programmable logic controller with a sensor that reads the pressure drop across the filter elements, which contributes to lower compressed air consumption and longer cartridge life. Larger dust is captured in the pre-clean chamber, protecting cartridges from overload of contaminants and ensuring longer life. Thermally insulated with stone wool and aluminum inserts. High temperature paint and suitable components allow working at temperatures up to 240°C.

Electrostatic filter ESP

Robust construction made from pressed stainless steel sheet. Suitable for floor installation and consists of modular blocks interconnected by mechanical connections and silicone seals, resistant to high temperatures up to 230-250° C. Designed according to the capacity of the system for which it is intended. Equipped with a programmable logic controller and sensors to ensure automatic operation using AMS (Automatic Monitoring System). The filtration system consists of: 1) Air intake channel; 2) Filtered air exhaust channel; 3) Damper system to eliminate section filtering; 4) The central body, inside of which electrostatic system installed filtration; 5) Mechanical cleaning system; 6) Lower hopper with a horizontal auger for transporting dust; 7) Inclined hopper for dust removal.

Fly Ash Transport Systems

Compact and reliable Minijet technology is suitable for potentially cohesive dusts, combined with patented Air Assist® technology for controlled air injection along conveying lines. Minimum air consumption during dense phase transport, limiting wear and maintenance.

A winning technology in all ash transport applications: from coal, fuel oil or biomass, even over long distances and high costs. The system is equipped with a special ceramic valve without rubber seals, which is able to resist wear and operate at temperatures up to 400°C. Fast installation and easy start-up: the system is pre-assembled, wired, tested and delivered ready to use. Adapted technologies to any project requirements for pneumatic fly ash transport. Meets the requirements for vacuum transportation of slag with particle sizes up to 3.5 mm.

Special components, properly coated with wear-resistant materials, provide reliable and flexible use.

Our projects